Views: 0 Author: Site Editor Publish Time: 2025-12-01 Origin: Site

The woodworking industry has seen remarkable advancements in technology, with machinery evolving to meet the increasing demand for precision, efficiency, and speed. Among the many innovations that have changed the landscape of modern woodworking, relief carving machines stand out as one of the most impactful. These machines have revolutionized the way woodworkers approach intricate designs, offering unparalleled levels of detail, consistency, and production speed.

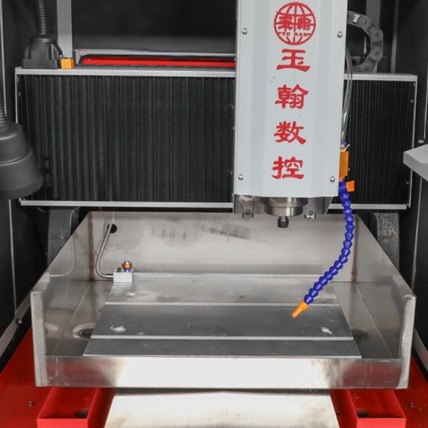

At Anhui Yuhan Numerical Control Technology Co., Ltd., we are proud to be at the forefront of providing relief carving machines that meet the demands of today’s woodworking industry. In this article, we’ll explore how these machines work, their benefits, and why they are crucial for achieving top-tier results in woodworking projects.

A relief carving machine is a specialized piece of equipment designed to create three-dimensional designs on wood surfaces. Unlike traditional carving methods, which rely heavily on manual labor and artistic skill, relief carving machines utilize advanced numerical control (NC) and computer numerical control (CNC) technologies to automate the carving process. These machines are programmed to follow precise instructions, allowing them to carve intricate patterns with high accuracy.

Relief carving is typically used for creating decorative details, ornamental designs, and even portraits or landscapes, making it an essential tool for industries such as furniture making, cabinetry, architectural woodwork, and artistic carving.

At Anhui Yuhan Numerical Control Technology Co., Ltd., our relief carving machines are engineered with advanced features to deliver both efficiency and precision. These machines seamlessly combine mechanical components, numerical control, and software programming to automate the carving process, resulting in high-quality, intricate woodwork. Here's a deeper look at how these machines operate:

Relief carving machines primarily rely on CNC technology (Computer Numerical Control) to carry out carving tasks with exceptional accuracy. The operator begins by designing a digital model of the carving using specialized CAD (Computer-Aided Design) software. Once the design is complete, it is converted into machine code, which the CNC system interprets. This code directs the carving machine on how to move, what tools to use, and the precise depth to carve. The accuracy of the machine code ensures that every detail of the carving is executed with precision, eliminating human error and allowing for intricate designs to be replicated consistently.

A hallmark of relief carving machines is their use of precision tooling. The cutting tools, often made from high-quality materials like tungsten carbide, are designed to cut through wood at various depths with sharpness and durability. These tools are mounted on a spindle, which can move along multiple axes. The machine adjusts the cutting depth in real-time, based on the programmed specifications, ensuring every part of the carving has a uniform finish. The ability to switch between different tool types and depths is key to creating fine details, such as textures and relief patterns, without compromising on quality.

The material—whether wood, MDF, or other composite materials—is securely placed on the machine’s work surface. Many modern relief carving machines are equipped with automated material handling systems, which can load, position, and stabilize the workpieces with high efficiency. This automation reduces the manual labor involved and speeds up the entire process, allowing for faster production times and improved consistency in carving.

To ensure consistent quality throughout the carving process, real-time monitoring systems are integrated into modern relief carving machines. These systems track the progress of the carving, monitoring parameters such as tool wear, material shifting, and machine performance. If any issues arise, the system alerts the operator, allowing for quick adjustments. This capability minimizes downtime, improves productivity, and ensures the carving is completed according to specifications.

These features combine to create a high-performance machine capable of producing detailed, precise carvings with speed and efficiency, making it a valuable asset for modern woodworking operations.

Relief carving machines offer a range of advantages that make them indispensable in the modern woodworking industry. Let’s dive into the key benefits:

The ability of relief carving machines to work at high speeds is one of their standout features. What would take an experienced artisan hours or even days to carve manually can now be completed in a fraction of the time. The automated process ensures that the design is replicated quickly, reducing the time spent on each piece and improving overall productivity.

One of the biggest challenges with manual carving is maintaining uniformity across multiple pieces. Even the most skilled artisans can struggle to replicate the same design with exact precision. With a relief carving machine, however, the CNC system ensures that each carving is exactly the same, maintaining high precision across large production runs. This consistency is critical for industries that require large quantities of identical pieces, such as cabinetry and furniture manufacturing.

Relief carving machines are capable of producing intricate and highly detailed designs that would be nearly impossible to achieve manually. Whether it's fine textures, deep reliefs, or complicated patterns, these machines can handle complex geometry with ease. This opens up a world of possibilities for woodworkers who want to push the boundaries of creativity.

By automating the carving process, relief carving machines reduce the need for manual labor, which translates into cost savings for businesses. Fewer workers are required to complete a project, and the speed of the machines means that fewer work hours are needed overall. Additionally, automation reduces the risk of human error, which can lead to costly mistakes.

The automated nature of relief carving machines allows for improved quality control. With every piece being carved to the exact same specifications, there’s less risk of defects or inconsistencies. Moreover, the machines can be calibrated to meet specific standards, ensuring that every product meets the highest quality criteria.

Relief carving machines are capable of working with a wide variety of materials beyond wood, including MDF, acrylic, and plastics. This versatility allows businesses to expand their offerings and work with different materials to meet client needs.

Relief carving machines are used across various sectors within the woodworking industry. Here are some common applications:

In furniture production, relief carving machines are widely used for decorative carvings on cabinets, doors, and tables. These intricate designs add an element of elegance and luxury to furniture, which is especially important in high-end or custom pieces.

Architectural woodwork, such as moldings, trims, and columns, often requires detailed carvings to achieve a classic, traditional look. Relief carving machines allow manufacturers to quickly and accurately create complex patterns on architectural elements, ensuring both precision and aesthetic appeal.

For artisans creating custom wood carvings, such as sculptures or portraits, relief carving machines provide an unparalleled level of precision and efficiency. The ability to replicate fine details is invaluable for creating high-quality artwork at a faster pace.

Wooden signs, plaques, and decorative pieces benefit greatly from the capabilities of relief carving machines. From text to elaborate imagery, these machines can carve intricate designs onto wooden surfaces, making them perfect for producing high-quality signage for businesses, homes, and public spaces.

For custom woodworking shops, relief carving machines are ideal for creating one-of-a-kind pieces with highly detailed designs. Whether it’s a custom gift or a unique decorative item, the machines enable woodworkers to offer products with intricate carvings that stand out from mass-produced alternatives.

If you’re looking to enhance your woodworking production and improve the efficiency and quality of your work, investing in a relief carving machine is a smart decision. These machines offer numerous advantages that go beyond manual carving, from faster production times to unmatched precision. Whether you are a large-scale manufacturer or a small custom shop, these machines provide the flexibility, speed, and accuracy needed to stay competitive in the ever-evolving woodworking industry.

At Anhui Yuhan Numerical Control Technology Co., Ltd., we specialize in providing relief carving machines that meet the highest standards of performance and quality. Our machines are designed to optimize your production process, reduce labor costs, and elevate the quality of your wood carvings.

In today’s woodworking industry, the need for precision, efficiency, and high-quality output has never been more critical. Relief carving machines provide woodworkers with the tools to meet these demands, offering unmatched speed, consistency, and the ability to create intricate designs with ease. By investing in these machines, businesses can improve their productivity, reduce costs, and create superior-quality products that stand out in the marketplace.

At Anhui Yuhan Numerical Control Technology Co., Ltd., we are proud to offer relief carving machines that help businesses achieve these goals. Our machines are built with advanced technology to ensure exceptional performance and precision. If you are looking to enhance your woodworking operations, we encourage you to reach out to us for expert guidance and assistance in selecting the right equipment for your needs.

This blog post provides a detailed exploration of relief carving machines and their impact on the modern woodworking industry. By focusing on efficiency, precision, and the specific advantages of these machines, we provide value to readers while highlighting Anhui Yuhan Numerical Control Technology Co., Ltd. as a trusted source for high-quality equipment.

content is empty!