Views: 0 Author: Site Editor Publish Time: 2026-01-13 Origin: Site

3D printing has revolutionized manufacturing, design, and personal projects in a way that was previously unimaginable. The ability to print three-dimensional objects from digital files has opened up a world of possibilities, from prototyping and producing spare parts to creating custom items and artwork. As the technology behind 3D printing continues to evolve, many people are left wondering: Can I print whatever I want on a 3D printer?

The simple answer is both yes and no. While 3D printers, especially those equipped with advanced 3D engraving machines, can print a wide variety of objects, there are limitations to what can be created, depending on the type of 3D printer, the materials used, and the complexity of the design. Understanding these limitations, along with the capabilities of modern 3D printing technology, is crucial to getting the most out of this versatile tool.

In this article, we will explore the world of 3D printing and answer the question of whether you can truly print anything you want. We'll cover the basics of how 3D printing works, what kinds of objects can be printed, the limitations of 3D printing, and the role of 3D engraving machines in expanding the scope of what can be created. By the end of this guide, you’ll have a clearer understanding of the possibilities and limitations that come with this exciting technology.

3D printing is a revolutionary technology that has dramatically expanded the possibilities for manufacturing and creation. Thanks to its versatility, 3D printing can be used to produce a wide variety of objects across industries, from prototypes and spare parts to jewelry and even food. However, the range of items that can be printed depends on several factors, including the material used, the printer's capabilities, and the type of design file. In this article, we’ll explore the different types of items that can be printed using 3D printers, highlighting the creative and practical uses of this exciting technology.

Types of Items You Can Print

Prototypes and Models

3D printing is widely used in the design and manufacturing industries for creating prototypes. Engineers and designers can quickly produce a 3D model of a new product, making it easier to test and evaluate before mass production. This is especially useful in industries such as automotive, aerospace, and electronics.

Custom Parts

You can print custom parts for machines, vehicles, or home appliances. 3D printers are capable of producing functional components that can replace broken parts or improve the performance of a device. For example, you might create a custom bracket or a small gear that’s no longer in production.

Art and Sculptures

One of the most exciting aspects of 3D printing is the ability to create intricate art and sculptures. Artists can use 3D printers to bring their visions to life with amazing precision. With the help of 3D engraving machines, artists can even engrave intricate designs onto their creations.

Jewelry and Fashion

The fashion industry has been quick to adopt 3D printing, particularly for custom jewelry designs. From rings and necklaces to entire fashion collections, 3D printing allows designers to experiment with shapes and materials that would be difficult or impossible to achieve with traditional methods.

Food

Yes, it’s possible to print food. 3D printers that are specifically designed for food materials can print complex food structures using ingredients like chocolate, dough, and pureed vegetables. While this technology is still in its infancy, it holds significant potential for the culinary world.

Medical Devices and Implants

In the medical field, 3D printing is being used to create customized prosthetics, implants, and even bioprinted tissue. This is a growing field, and 3D printers are being used to make items that are tailored to the individual needs of patients.

While 3D printers are capable of creating a wide variety of items, there are limitations that should be considered when planning what to print.

Not all materials can be used in 3D printers. The most common materials include:

Plastic (PLA, ABS)

Metal (stainless steel, titanium)

Resin (used in SLA printers)

Food-safe materials (for food printers)

Some 3D printers are designed for specific materials, and using the wrong material can lead to subpar results or even damage the printer. Moreover, 3D printed objects can lack the strength or flexibility of traditionally manufactured items unless the right materials are used.

Most consumer-grade 3D printers have a relatively small build area. If you want to print large items, you may need access to an industrial-grade printer with a larger print bed. However, larger items can still be printed in parts and assembled later, though this can limit the overall design.

The detail that can be achieved with a 3D printer depends on its resolution. 3D printers have varying levels of precision, and printers with lower resolution might leave visible layers or imperfections on the surface of the printed item. If high detail is required, a 3D engraving machine can be used to refine the details.

3D printing is a slow process, especially for large or highly detailed objects. Depending on the size and complexity of the design, the printing process can take hours or even days. This is not ideal for mass production but is perfect for creating one-off designs or prototypes.

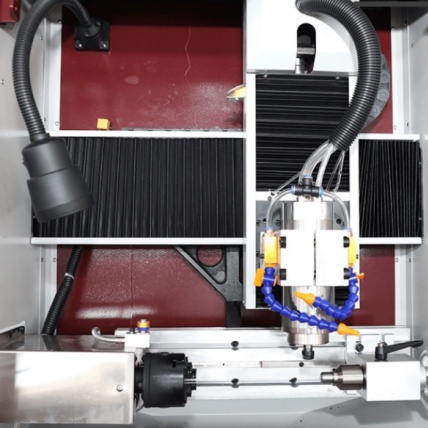

While 3D printing creates solid objects, 3D engraving machines take the process a step further by adding intricate designs to the surface of these printed items. This technology allows for the customization of products, offering an additional layer of functionality to the 3D printing process. Through precise engraving, manufacturers and artists can enhance their creations with logos, text, patterns, and even detailed images, transforming a simple print into a personalized work of art.

3D engraving machines are capable of etching fine details into a wide variety of materials, such as metals, plastics, wood, and even ceramics. This makes them incredibly useful in many industries, including jewelry, automotive, manufacturing, and promotional goods. For instance, a jewelry designer could use a 3D engraving machine to add personalized engravings to a necklace or ring, while a manufacturer could use it to engrave serial numbers or branding onto products.

By integrating 3D engraving with 3D printing, businesses can create unique and personalized products on demand, offering customized solutions for customers. This synergy not only enhances the aesthetic appeal of the final product but also increases its value and originality, making it a vital tool for businesses aiming to stand out in a competitive market.

Feature | 3D Printing | 3D Engraving Machine |

Function | Builds 3D objects layer by layer | Adds intricate details or patterns to surfaces |

Applications | Prototyping, custom parts, art, jewelry | Personalization, texturing, logos, patterns |

Material Compatibility | Plastics, metals, resins, food | Works on already printed or existing surfaces |

Precision | Variable precision based on the printer | High precision engraving, ideal for details |

When considering whether 3D printing is worth the investment, it’s important to evaluate the specific needs and objectives of your projects. 3D printing offers unparalleled flexibility, allowing you to create highly customized parts and prototypes with precision and efficiency. For industries such as manufacturing, automotive, aerospace, and even creative fields like jewelry design and art, 3D printing is a game-changer. It allows you to bring complex ideas to life quickly, with the ability to make rapid design iterations without the need for expensive molds or tooling.

Additionally, 3D engraving machines can take your designs a step further by allowing you to engrave intricate details on a wide variety of materials. Whether you are producing custom signage, detailed art pieces, or personalized products, a 3D engraving machine can significantly enhance the quality, uniqueness, and precision of the final product.

At Anhui Yuhan Numerical Control Technology Co., Ltd., we recognize the expansive potential of 3D printing and engraving technology. Our advanced 3D printers and engraving machines are designed to meet the diverse needs of our clients, from prototyping to intricate customization. If you’re ready to unlock the capabilities of 3D technology, our team is here to offer expert guidance and high-performance solutions to bring your projects to life.

Can I print any object with a 3D printer?

While 3D printers are versatile, there are limitations based on material compatibility, printer resolution, and size constraints. Not all objects can be printed due to these factors.

What is the difference between 3D printing and 3D engraving?

3D printing creates solid objects from a digital design, while 3D engraving involves adding detailed designs to the surface of an already printed or solid object.

Can I use a 3D printer for mass production?

3D printing is generally better for prototypes, custom designs, or one-off pieces. For mass production, traditional manufacturing methods are more efficient.

What materials can I use with a 3D printer?

Most 3D printers are compatible with plastics (PLA, ABS), resins, and metals. Specific printers may support additional materials, depending on their design.

content is empty!